Our aluminum cans can be recycled over and over.

95%

energy savings is achieved through recycling.

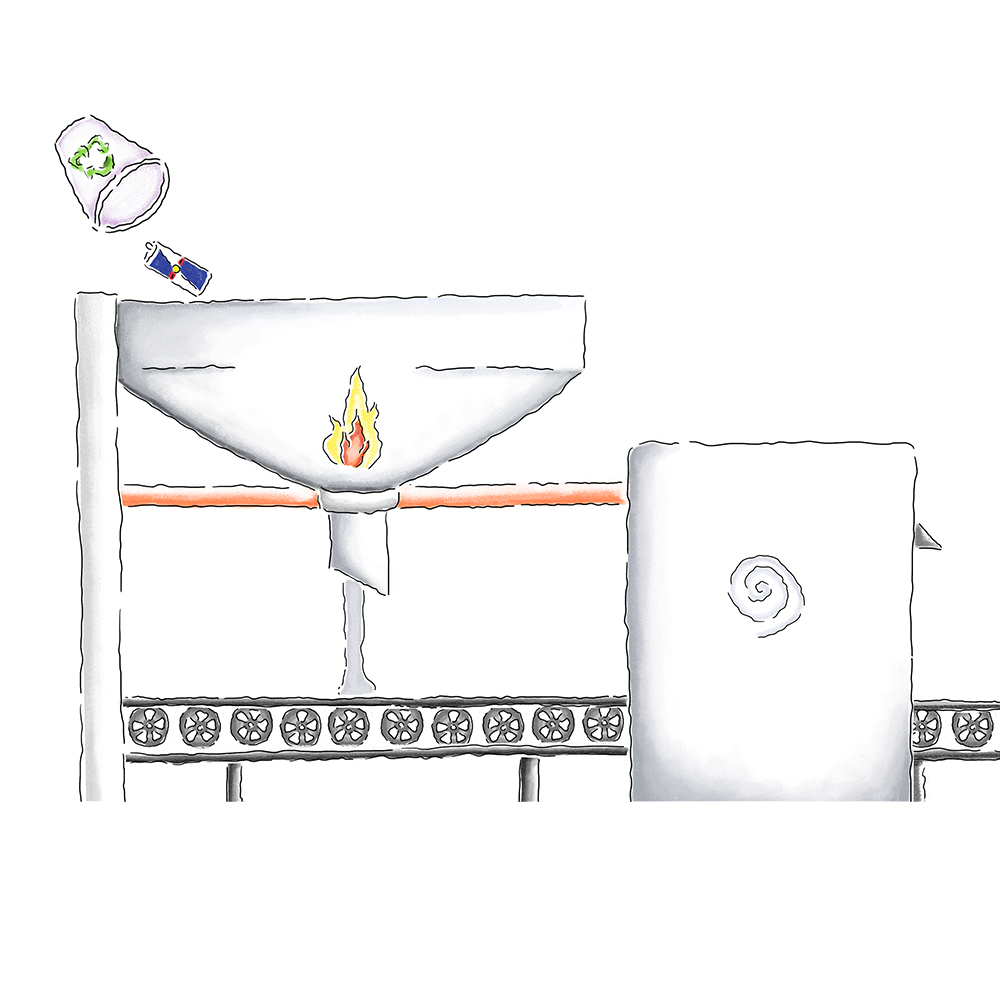

The aluminum can is one of very few food packages that can be almost completely recycled – it can even be melted down and recycled an unlimited number of times without any loss of quality. This is a decisive advantage because recycling aluminum uses 95% less energy than producing aluminum from raw materials.

Aluminum cans are strong and sturdy, yet light in weight, neutral in taste, compact in shape and light-proof. In addition, their efficient shape and low weight enable reduced CO₂ emissions in transport compared to glass and plastic bottles.

Recycling

You can melt down and recycle aluminum cans over and over, a sustainable advantage compared to other beverage packaging.

Saving energy

Recycling aluminum uses 95% less energy than producing aluminum from raw materials.

Lifecycle

Aluminum is one of the fastest materials in terms of recycling. Efficient recycling can turn a used can into a new one again within 60 days.

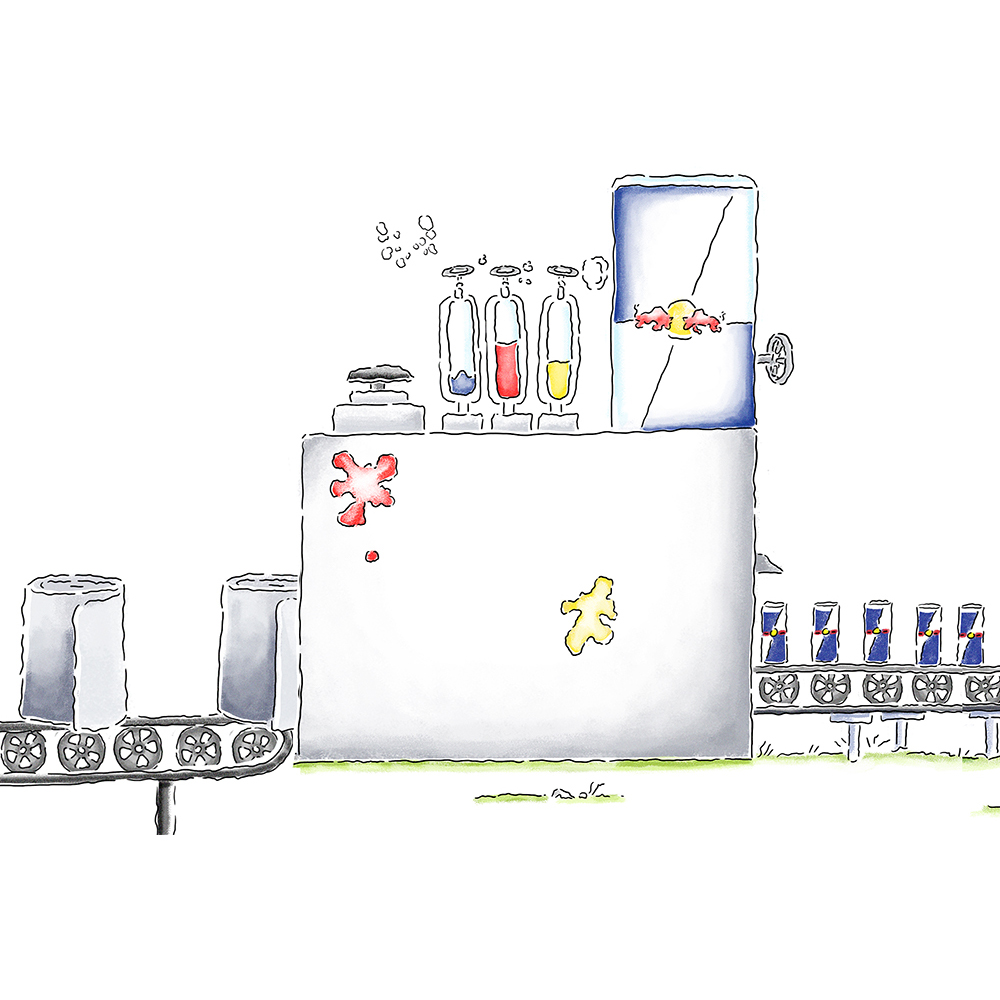

We consistently produce in a resource-conserving manner.

Energy

We aim for the latest energy efficient equipment in filling and integrated recycling processes for all production.

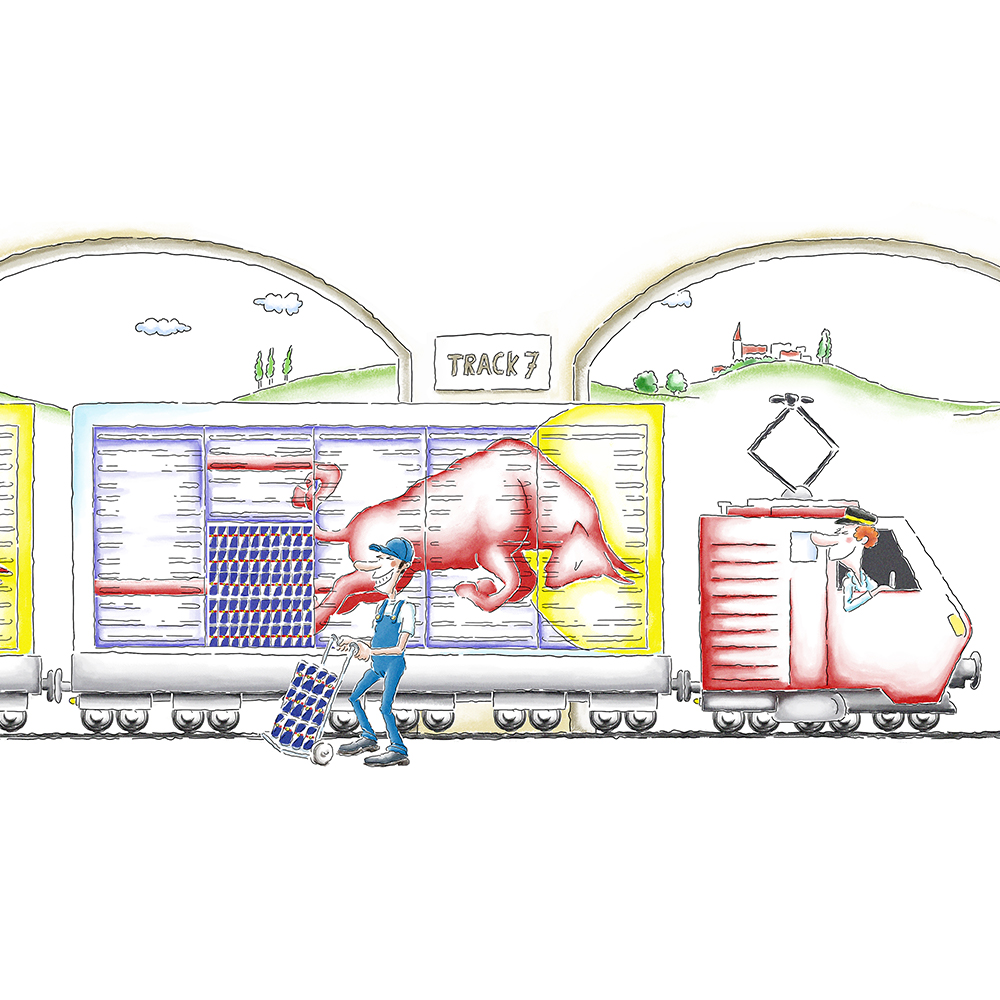

We were able to minimize empty can transport distances in our main production sites in the US due to the so-called "through-the-wall production". In this innovative process, the production of beverage and can as well as the filling are carried out on site. After filling, we transport the majority of the cans by rail to various conveniently located ports and then by ship all over the world.

New technologies

Thanks to the very much centralized production, new technologies can be implemented quickly, which contributes to conserving natural resources.

Regional ingredients

We also make efforts to source ingredients locally, including water and sugar, which helps ensure consistent production quality.

LEED Silver Certified

The new US filling-plant is set up to a high sustainability standard. The plant is “ISO 14001” and “LEED Silver” certified. Check here for more info.

We strive to transport our products in an environmentally friendly way.

40%

The transport of glass bottles requires 40% more space compared to aluminum cans.

At Red Bull, our production methods help reduce emissions in transport and product cycles. The compact and lightweight aluminum can is a key factor in reducing CO₂ during transport, packaging and storage. When it comes to transport, compared to aluminum cans plastic containers require 20% more space and glass bottles require 40% more space due to their shape. In addition, we prefer the most climate-friendly modes of transport whenever possible.

40%

Due to their shape, the transport of glass bottles requires 40% more space compared to aluminum cans.

20%

Due to their shape, the transport of plastic bottles requires 20% more space compared to aluminum cans.

11g (250ml)

We are continuously working to reduce the weight of our packaging where possible. Less weight means less shipping fuel and a smaller environmental footprint.

Red Bull Coolers contribute to a lower environmental impact

Red Bull Coolers contribute to a lower environmental impact through natural refrigerants, energy-efficient fans, smart temperature and light regulating devices. In addition, we are continuously working on technical improvements and optimizing our portfolio to reduce our carbon emissions.